In the current society, pneumatic tires or polyurethane wheels are used in the market, so this type of lifting platform has a very good texture and can be used in places such as home floors during use. Therefore, this mobile lifting platform will not cause damage to the ground during use, making it very convenient to use. The elevator is made of manganese steel, especially its theme frame, the faster the lifting speed.

The safety of a fixed loading and unloading platform is high. The platform device is made of steel plate, and there are many protrusions on it, which increase the friction force of the goods. The slide of the goods caused by low friction is placed to complete the damage of the goods. This design can effectively prevent slipping, and the entire design is safe and easy to operate.

.That's a very high consumption in some places. For 2 tons of goods to be loaded, unloaded, and transferred 10 people need to work continuously for several hours, using forklifts to operate, and multiple forklifts need to work simultaneously for one or two hours. Moreover using forklifts also requires professional forklift drivers, and the cost of using them is often high. So, that is the application of fixed loading and unloading platforms. A fixed loading and unloading platform is an auxiliary equipment that mainly completes the rapid loading and unloading of goods. It has an adjustment function, and the truck has a certain height to cross when transporting goods from the warehouse to the truck. However, a fixed loading and unloading platform can adjust the height, serving as a bridge, connecting the truck and warehouse, and meeting a large number of cargo handling needs, But such a large workload requires only one operator to operate, greatly saving labor costs and manpower, improving the production efficiency of the enterprise.

The advantages of fixed loading and unloading platforms are that the application of fixed loading and unloading platforms is more energy-efficient than ordinary loading and unloading platforms. The automatic adjustment of the lifting height meets the requirements of cargo transportation, saves time for loading and unloading, and is convenient to operate. The entire loading and unloading process has high safety, and the design is more detailed than ordinary loading and unloading platforms, ensuring smooth transportation and quality of goods.

The safety of a fixed loading and unloading platform is high. The platform device is made of steel plate, and there are many protrusions on it, which increase the friction force of the goods. The slide of the goods caused by low friction is placed to complete the damage of the goods. This design can effectively prevent slipping, and the entire design is safe and easy to operate.

So what are the characteristics of mobile lifting platforms?

If there are problems inside the elevator and electrical professionals are present, any components of the hydraulic system should be disassembled and repaired in a completely depressurized condition.

That's a very high consumption in some places. For 2 tons of goods to be loaded, unloaded, and transferred, 10 people need to work continuously for several hours, using forklifts to operate, and multiple forklifts need to work simultaneously for one or two hours. Moreover, using forklifts also requires professional forklift drivers, and the cost of using them is often high. So, that is the application of fixed loading and unloading platforms. A fixed loading and unloading platform is an auxiliary equipment that mainly completes the rapid loading and unloading of goods. It has an adjustment function, and the truck has a certain height to cross when transporting goods from the warehouse to the truck. However, a fixed loading and unloading platform can adjust the height, serving as a bridge, connecting the truck and warehouse, and meeting a large number of cargo handling needs, But such a large workload requires only one operator to operate, greatly saving labor costs and manpower, improving the production efficiency of the enterprise.

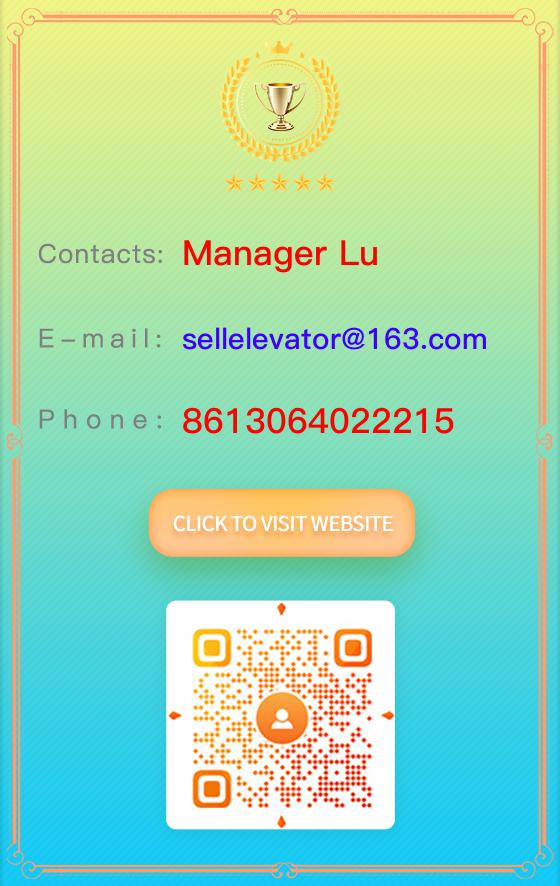

Recommendation and consultation.The reason why many fields choose to use the electric elevator is that it can not only save manpower but also facilitate people's life in the process of use. The important thing is to solve the handling work, so that the electric elevator can be used to carry goods upstairs and downstairs. When transporting goods, the first thing everyone should pay attention to is its carrying capacity. Generally, around 500 kilograms of goods can be transported, unloaded, and transferred, 10 people need to work continuously for several hours,WiesbadenHydraulic unloading platform, and multiple forklifts need to work simultaneously for one or two hours. Moreover using forklifts also requires professional forklift drivers,WiesbadenCylinder mounted hydraulic lifting platform, and the cost of using them is often high. So is there any way to meet both the rapid loading and unloading of goods and the low-cost needs? Of course there is, that is the application of fixed loading and unloading platforms. A fixed loading and unloading platform is an auxiliary equipment that mainly completes the rapid loading and unloading of goods. It has an adjustment function, and the truck has a certain height to cross when transporting goods from the warehouse to the truck. However, a fixed loading and unloading platform can adjust the height, serving as a bridge, connecting the truck and warehouse, and meeting a large number of cargo handling needs, But such a large workload requires only one operator to operate, greatly saving labor costs and manpower, improving the production efficiency of the enterprise.

So what are the characteristics of mobile lifting platforms?

Total quality management.When people choose mobile lifting platforms, it is important to pay attention to their structural stability, as it directly affects whether the entire lifting platform can operate smoothly. If it has high strength and stable operation,WiesbadenHydraulic loading and unloading platform, it can support the design of the mechanism, and it is very scientific. Therefore, during use, it can ensure the overall structure is safe, stable, and reassuring.

Just like when there is a malfunction in the walking part of the lifting platform operators must master common knowledge of equipment maintenance faults, so that they do not appear too flustered when a malfunction occurs. Generally speaking, the common faults of the walking part of the lifting platform are divided into:; Fault problems such as bearing bush burning, axle box bearing burning, traction motor bearing burning, tire relaxation, collapse, etc. Below, pneumatic tires or polyurethane wheels are used in the market, so this type of lifting platform has a very good texture and can be used in places such as home floors during use. Therefore, this mobile lifting platform will not cause damage to the ground during use making it very convenient to use. The elevator is made of manganese steel, especially its theme frame, which is not easy to corrode during use and is important for convenient storage.

Wiesbaden.I believe many people are familiar with mobile lifting platforms. In daily life, we often see many fields using this lifting platform, but we need to pay attention to details during the use process.

When people choose mobile lifting platforms, it is important to pay attention to their structural stability, as it directly affects whether the entire lifting platform can operate smoothly. If it has high strength and stable operation, it can support the design of the mechanism, and it is very scientific. Therefore, during use, it can ensure the overall structure is safe, stable, and reassuring.

That's a very high consumption in some places. For 2 tons of goods to be loaded, unloaded, and transferred, 10 people need to work continuously for several hours, and multiple forklifts need to work simultaneously for one or two hours. Moreover, using forklifts also requires professional forklift drivers, and the cost of using them is often high. So, is there any way to meet both the rapid loading and unloading of goods and the low-cost needs? Of course there is, that is the application of fixed loading and unloading platforms. A fixed loading and unloading platform is an auxiliary equipment that mainly completes the rapid loading and unloading of goods. It has an adjustment function, and the truck has a certain height to cross when transporting goods from the warehouse to the truck. However, a fixed loading and unloading platform can adjust the height, serving as a bridge, connecting the truck and warehouse, and meeting a large number of cargo handling needs, But such a large workload requires only one operator to operate, greatly saving labor costs and manpower, improving the production efficiency of the enterprise.

WiesbadenHydra

WiesbadenHydra WiesbadenElect

WiesbadenElect