These devices are also relatively easy to operate during use and should be able to achieve goals and requirements.

The situation and content of the lifting platform are very crucial. During the process, the current and other operations are also crucial. In order to make the heavy object descend smoothly, improve the safety and reliability of braking, as well as its lifting speed, Make it more reliable and secure. Overall, when selecting and using equipment, one should understand the working principle, some information about the lifting platform, and be able to consider some design principles and situations when operating.

Columbus.Of course, when choosing a lift, it is also necessary to consider its production. If a manufacturer has a large production capacity, it indicates its strong strength, especially the construction lift has relatively high requirements for production technology. Therefore, when making a purchase, it is important to consider the factory building and process of its production, all of which are very important.

The situation and content of the lifting platform are very crucial. During the process, the current and other operations are also crucial. In order to make the heavy object descend smoothly, improve the safety and reliability of braking, as well as its lifting speed, Make it more reliable and secure. Overall, when selecting and using equipment, one should understand the working principle, and be able to consider some design principles and situations when operating.

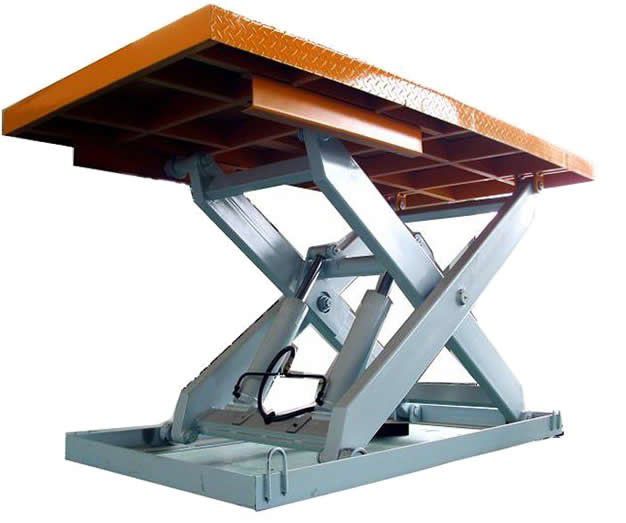

.In the past, in large workshops,Columbus2 ton electric lifting platform, if goods had to be transferred from one place to another, it would be very expensive. For loading, unloading, and transferring 2 tons of goods, it would require 10 people to work continuously for several hours, using forklifts to operate and multiple forklifts to work simultaneously for one or two hours. Moreover, using forklifts also required professional forklift drivers, and the cost of using them was often high. Is there any way to do this, Can it meet both rapid loading and unloading of goods and low-cost needs? Of course there is, that is the application of fixed loading and unloading platforms. A fixed loading and unloading platform is an auxiliary equipment that mainly completes the rapid loading and unloading of goods. It has an adjustment function, and the truck has a certain height to cross when transporting goods from the warehouse to the truck. However a fixed loading and unloading platform can adjust the height, connecting the truck and warehouse serving as a bridge, and meeting a large number of cargo handling needs But such a large workload requires only one operator to operate, greatly saving labor costs and manpower, improving the production efficiency of the enterprise.

The advantages of fixed loading and unloading platforms are that the application of fixed loading and unloading platforms is more energy-efficient than ordinary loading and unloading platforms. The automatic adjustment of the lifting height meets the requirements of cargo transportation, saves time for loading and unloading, and is convenient to operate. The entire loading and unloading process has high safety, and the design is more detailed than ordinary loading and unloading platforms, ensuring smooth transportation and quality of goods.

The advantages of fixed loading and unloading platforms are that the application of fixed loading and unloading platforms is more energy-efficient than ordinary loading and unloading platforms. The automatic adjustment of the lifting height meets the requirements of cargo transportation, and is convenient to operate. The entire loading and unloading process has high safety, and the design is more detailed than ordinary loading and unloading platforms, ensuring smooth transportation and quality of goods.

The function of fixed loading and unloading platform The fixed loading and unloading platform meets the loading and unloading needs of goods, and has good load-bearing effect, convenient loading and unloading, low consumption, and the height can be adjusted, lifted to the appropriate position to meet the loading and unloading of goods. The later maintenance is in place and the maintenance cost is low.

High stability of manufacturing materials. Usually, manufacturers can choose a variety of manufacturing materials when producing fixed loading and unloading platforms, and each material brings different effects when used. For many manufacturers, in order to improve the stability of loading and unloading platforms during use, they attach great importance to the selection of manufacturing materials. Generally, materials with high stability will be used as much as possible, as such materials can achieve better results in application.

The advantages of fixed loading and unloading platforms are that the application of fixed loading and unloading platforms is more energy-efficient than ordinary loading and unloading platforms. The automatic adjustment of the lifting height meets the requirements of cargo transportation, saves time for loading and unloading, and is convenient to operate. The entire loading and unloading process has high safety, and the design is more detailed than ordinary loading and unloading platforms, ensuring smooth transportation and quality of goods.

quality.When using an electric lifting platform, it should be possible to follow the correct operating method, and during the design process, relevant debugging should be carried out to ensure that all key technical indicators meet the design requirements. When using, the electrical system should also be connected to the power supply and meet the specified operating range and standards before operation can be carried out. At the same time, when conducting inspections, so that they can be used more smoothly in the later stage.

When operating an electric lifting platform, people should be able to follow the direction and check some basic operating systems in the early stage. During the use process, these parts should be better designed and meet certain quality requirements when working in the air. The center of the loaded machine should be in the center position of the workbench. During activities, it is important to understand the usage of these devices. Protective barriers play a very important role in protecting them. When adjusting these directions or starting the motor system during use, it should be possible to pull them to these designated positions for operation, in order to achieve better work.

The safety of a fixed loading and unloading platform is high. The platform device is made of steel plate, and there are many protrusions on it, which increase the friction force of the goods. The slide of the goods caused by low friction is placed to complete the damage of the goods. This design can effectively prevent slipping, and the entire design is safe and easy to operate.

The situation and content of the lifting platform are very crucial. During the process,ColumbusSuper large lifting platform, the current and other operations are also crucial. In order to make the heavy object descend smoothly, improve the safety and reliability of braking, and also understand the balance situation during the setting process. It can maintain pressure and prevent the descent speed from being affected by heavy objects, as well as its lifting speed, Make it more reliable and secure. Overall, when selecting and using equipment, one should understand the working principle, some information about the lifting platform,ColumbusVertical lifting platform, and be able to consider some design principles and situations when operating.

For more, please check.When using an electric lifting platform, it should be possible to follow the correct operating method, and during the design process, relevant debugging should be carried out to ensure that all key technical indicators meet the design requirements. When using, the electrical system should also be connected to the power supply and meet the specified operating range and standards before operation can be carried out. At the same time, when conducting inspections, the systems of these platforms are also very important. They should be able to check for any leakage, so that they can be used more smoothly in the later stage.

When there is a power outage, manual emergency descent can be used, which is safe, convenient fast, and practical.

Efficiency. However, there are quite a few elevator manufacturers on the market now, and when making purchases, it is necessary to choose according to individual needs.

Columbus.During the operation of electric elevators it is crucial for people to be able to understand the characteristics and situations of other precautions. Many technical personnel also need to combine other platform issues and contents to determine when operating, so that the transportation and use of these lifting platforms and goods can achieve better results and protection.

The situation and content of the lifting platform are very crucial. During the process, the current and other operations are also crucial. In order to make the heavy object descend smoothly improve the safety and reliability of braking, and also understand the balance situation during the setting process. It can maintain pressure and prevent the descent speed from being affected by heavy objects, as well as its lifting speed, when selecting and using equipment, one should understand the working principle, some information about the lifting platform, and be able to consider some design principles and situations when operating.

Efficiency. However, there are quite a few elevator manufacturers on the market now, and when making purchases, it is necessary to choose according to individual needs.

ColumbusTiltin

ColumbusTiltin