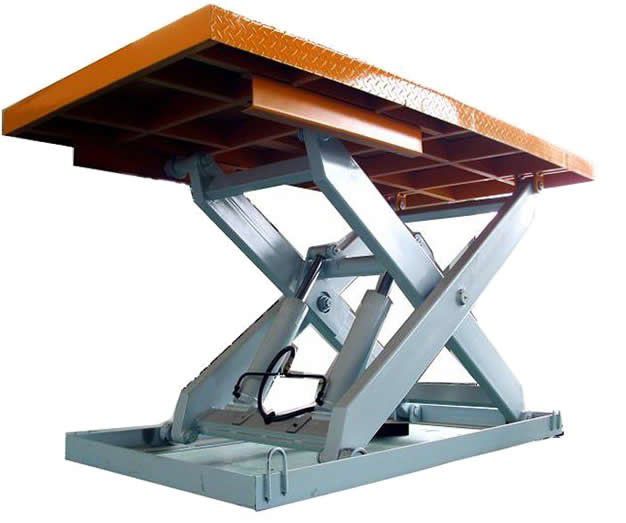

In the past, in large workshops, if goods had to be transferred from one place to another, unloading, and transferring 2 tons of goods, it would require 10 people to work continuously for several hours, using forklifts to operate and multiple forklifts to work simultaneously for one or two hours. Moreover, using forklifts also required professional forklift drivers, and the cost of using them was often high. Is there any way to do this, Can it meet both rapid loading and unloading of goods and low-cost needs? Of course there is, that is the application of fixed loading and unloading platforms. A fixed loading and unloading platform is an auxiliary equipment that mainly completes the rapid loading and unloading of goods. It has an adjustment function,Lexlip50 ton lifting platform, and the truck has a certain height to cross when transporting goods from the warehouse to the truck. However, a fixed loading and unloading platform can adjust the height, serving as a bridge, connecting the truck and warehouse, and meeting a large number of cargo handling needs, But such a large workload requires only one operator to operate, greatly saving labor costs and manpower, improving the production efficiency of the enterprise.

When using equipment people will consider different information and situations, and reference them based on these elements. Therefore, when using electric elevators, it can bring better work efficiency to people, and also enable them to achieve certain efficiency during the use process. Many manufacturers can cooperate with some very professional companies when designing products. Because material selection also meets strict requirements and standards, it can provide customers with better quality choices when designing products.

Lexlip.The pump station adopts a joint venture pump station and an Italian imported pump station. If the speed requirement is too high, a joint venture customized pump station is used to meet the ideal delivery requirements. The oil cylinder and sealing components of the lifting platform lifting cargo elevator guide rail type lifting platform use imported components to solve the problem of unstable oil pressure and oil leakage of components for customers.

When operating an electric lifting platform, people should be able to follow the direction and check some basic operating systems in the early stage. During the use process, these parts should be better designed and meet certain quality requirements when working in the air. The center of the loaded machine should be in the center position of the workbench. During activities, it is important to understand the usage of these devices. Protective barriers play a very important role in protecting them. When adjusting these directions or starting the motor system during use, it should be possible to pull them to these designated positions for operation, in order to achieve better work.

.When using equipment, people will consider different information and situations,Lexlip2 ton mobile lifting platform, and reference them based on these elements. Therefore, when using electric elevators, it can bring better work efficiency to people, and also enable them to achieve certain efficiency during the use process. Many manufacturers can cooperate with some very professional companies when designing products. Because material selection also meets strict requirements and standards, it can provide customers with better quality choices when designing products.

The advantages of fixed loading and unloading platforms are that the application of fixed loading and unloading platforms is more energy-efficient than ordinary loading and unloading platforms. The automatic adjustment of the lifting height meets the requirements of cargo transportation, saves time for loading and unloading, and is convenient to operate. The entire loading and unloading process has high safety, and the design is more detailed than ordinary loading and unloading platforms, ensuring smooth transportation and quality of goods.

The advantages of fixed loading and unloading platforms are that the application of fixed loading and unloading platforms is more energy-efficient than ordinary loading and unloading platforms. The automatic adjustment of the lifting height meets the requirements of cargo transportation saves time for loading and unloading, and is convenient to operate. The entire loading and unloading process has high safety, ensuring smooth transportation and quality of goods.

The professional information of aluminum alloy lifting platforms and the development of different equipment are crucial. In the process of understanding, one should be able to understand and pay attention to its automation, as well as understand its innovation in use. Many professional designers will learn about the information of these lifting platforms and their specific usage situations when designing platforms.

Mobile lifting platforms are divided into: four wheel mobile lifting platforms two wheel traction lifting platforms, modified car lifting platforms, hand push lifting platforms, hand operated lifting platforms, AC/DC dual purpose lifting platforms, car mounted lifting platforms, self-propelled lifting platforms, diesel engine curved arm self lifting platforms, folding arm lifting platforms sleeve type lifting platforms, and aluminum alloy lifting platforms.

The information and situation of the selection of electric lifting platforms are very important. When operating them, it is necessary to be able to follow these correct operating methods. Moreover, when using these lifting platforms, people can have a better understanding of the methods of closing switches, or the situation of each automatic design aspect. When using these platforms, they can improve their efficiency and pay attention to these different information.

technical service.The advantages of fixed loading and unloading platforms are that the application of fixed loading and unloading platforms is more energy-efficient than ordinary loading and unloading platforms. The automatic adjustment of the lifting height meets the requirements of cargo transportation, saves time for loading and unloading, and is convenient to operate. The entire loading and unloading process has high safety, and important components are very important when using a lifting platform. When making a selection, the lifting platform should be able to understand the specific working principle during use. When operating, it is formed by a vane pump with a certain pressure and can be operated through oil filter directional valves, throttle valves, etc, It can make its activity upward and lift heavy objects. During operation, the pressure can be adjusted, people should be able to follow the direction and check some basic operating systems in the early stage. During the use process, these parts should be better designed and meet certain quality requirements when working in the air. The center of the loaded machine should be in the center position of the workbench. During activities, it is important to understand the usage of these devices. Protective barriers play a very important role in protecting them. When adjusting these directions or starting the motor system during use, it should be possible to pull them to these designated positions for operation, in order to achieve better work.

These devices are also relatively easy to operate during use and should be able to achieve goals and requirements.

Installation conditions.The advantages of fixed loading and unloading platforms are that the application of fixed loading and unloading platforms is more energy-efficient than ordinary loading and unloading platforms. The automatic adjustment of the lifting height meets the requirements of cargo transportation, saves time for loading and unloading, and is convenient to operate. The entire loading and unloading process has high safety, and the design is more detailed than ordinary loading and unloading platforms ensuring smooth transportation and quality of goods.

There are many options for highlight styling. In fact, although types of lifting equipment can also bring certain effects during use, their design is relatively limited. Basically, the styles and shapes of lifting equipment in the market are similar. And aluminum alloy elevators are different because the plasticity of aluminum alloy materials is very strong. In the production process, it can also well meet some complex styling needs. The lifting equipment processed in this way will naturally have good sales in the market. After all, it has a wide range of styling options and can be well satisfied

When operating an electric lifting platform, people should be able to follow the direction and check some basic operating systems in the early stage. During the use process,LexlipPit lifting platform, these parts should be better designed and meet certain quality requirements when working in the air. The center of the loaded machine should be in the center position of the workbench. During activities, it is important to understand the usage of these devices. Protective barriers play a very important role in protecting them. When adjusting these directions or starting the motor system during use, it should be possible to pull them to these designated positions for operation, learning about these automated information and systems through different channels and channels can help one make the right choices. In fact, some professional companies can help people understand the situation of these products, learn about fixed and special products, and design them according to customer needs, To achieve better results, in the overall process of equipment design, people will have better choices for these lifting platforms, and also pay attention to some related performance characteristics and operational aspects, and pay attention to issues.

The design of the product and some related situations are all very important. Moreover, learning about these automated information and systems through different channels and channels can help one make the right choices. In fact, many products come in different types. When choosing electric elevators, some professional companies can help people understand the situation of these products, learn about fixed and special products, and design them according to customer needs, To achieve better results, in the overall process of equipment design, people will have better choices for these lifting platforms, and also pay attention to some related performance characteristics and operational aspects, and pay attention to issues.

When using equipment, people will consider different information and situations, and reference them based on these elements. Therefore, when using electric elevators, it can bring better work efficiency to people, and also enable them to achieve certain efficiency during the use process. Many manufacturers can cooperate with some very professional companies when designing products. Because material selection also meets strict requirements and standards, it can provide customers with better quality choices when designing products.

LexlipElectric

LexlipElectric LexlipFixed hy

LexlipFixed hy